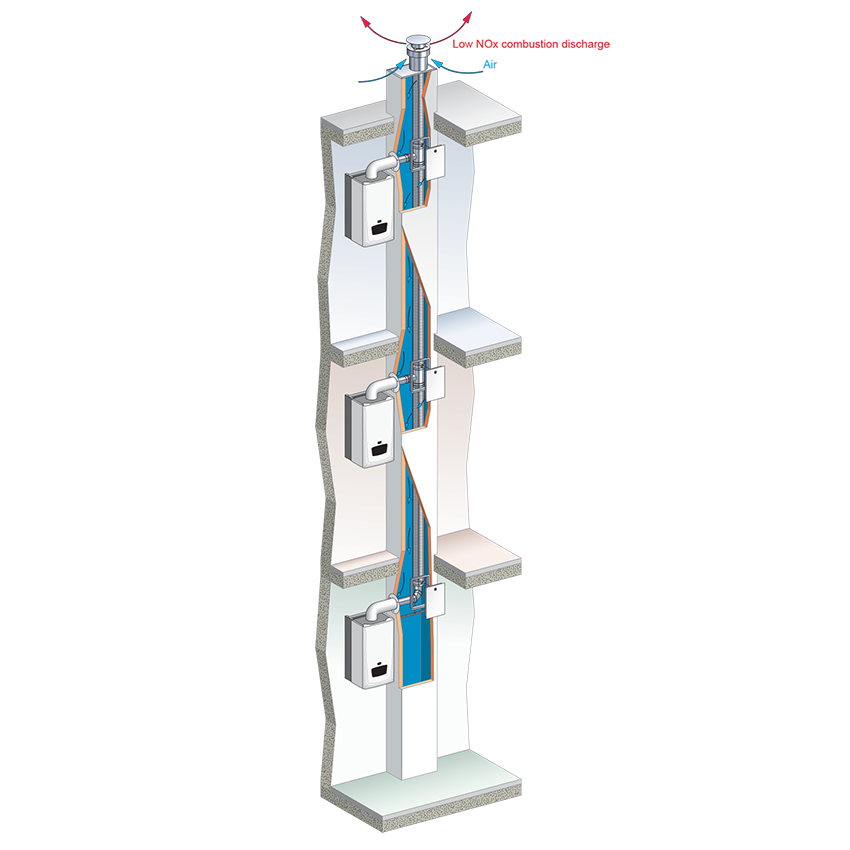

Cascade Flue – Design

Our first option is the concentric vertical cascade system and is the favourite for new build applications. This a stainless-steel pipe within a pipe principle which replicates a standard boiler flue, with the inner pipe being the flue discharge and gap between the inner and outer pipe being the air supply to each boiler. At each level you can have either one or two branch connections to connect to the apartment boilers. The concentric system is installed in an accessible service riser cupboard in a communal hallway as it will have flue joints at least at every 1m interval.

This system is designed, supplied, installed, commissioned and certified by Gemtex.

Our second system uses a flexible flue liner which allows for continuous runs without the need for multiple joints which results in only one flue inspection hatch required per boiler connection. The flue liner connects to the flue terminal where it then drops down the purpose made duct connecting to all the boilers on the installation through the “T” piece provided. Using a twin flue pipe system each boilers exhaust and air intake flue pipes enter the purpose-built duct where the exhaust pipe connects to the communal flue. The air intake flue pipe takes air for combustion from the purpose-built duct, the air enters this duct through the unique flue terminal situated on the roof space. The flexible flue liner system is available in both stainless steel and Polypropylene depending on the application.

This system is designed, supplied, installed, commissioned and certified by Gemtex but can also be installed via the mechanical contractor if required.